Information / About honing

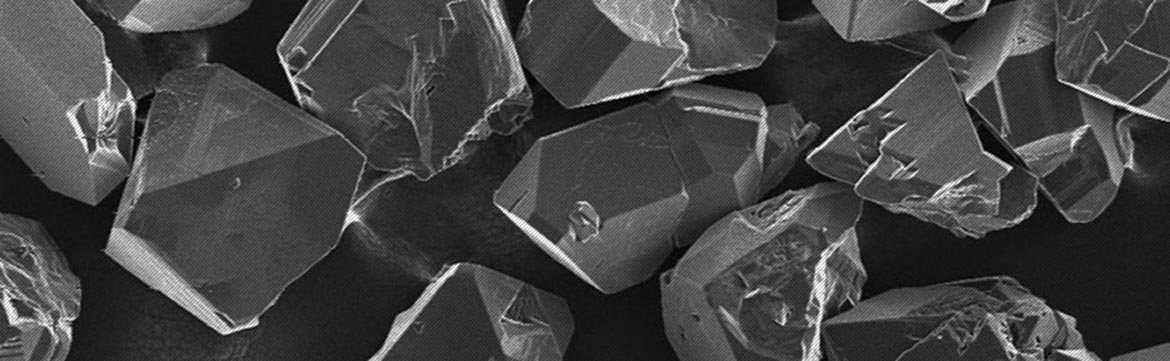

The super-abrasives are renowned for their hardness, abrasion resistance as well as for the superior thermal conductivity when compared to the traditional one, therefore, providing quality and productivity gain.

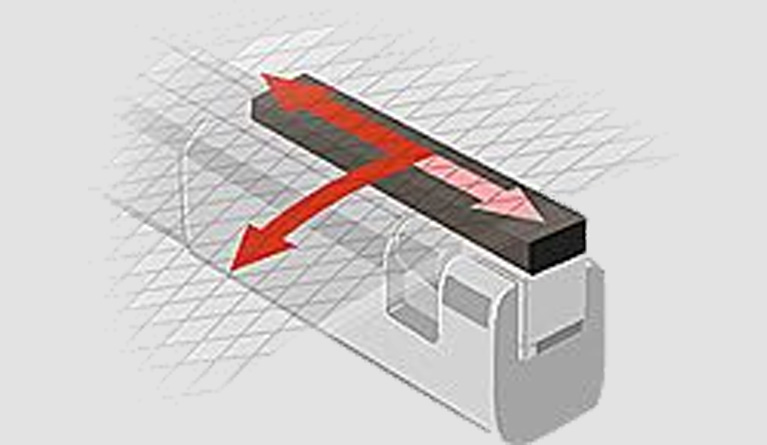

The cooling liquids used for honing are important for the durability of the tool and for the material removal. The use of these liquids should be plentiful and well-directed to the contact points of the stick and the tool.

Honing is a process that requires a machine, implements, a tool and oil. The highest cost in the honing procedure is the workmanship.

Among the advantages of honing we can find oil consume decrease and roundness removal.

The diamond honing tools have been developed in order to substitute the traditional silicon carbide and aluminum oxide stones with these objectives:

- Decrease the resistance of the material to suffer the honing;

- Increase the material removal with high dimension quality;

- Increase the durability.

The diamond honing tools guarantee excelent results in the milling of tempered and non-tempered steel, fusible iron and other types. One of the most important characteristics of the honing line is the diamond cover, wich allows work with cut speed and low contact pressure. The facts decrease the operation temperature, improving the final result and permitting the honing process to be done to thinner walls holes.

Note: Pictures are courtesy of Diamond Innovations, Inc.

Related Topics

What is the honing process?

Diamonds and Borazon honing stones advantages

Companies with benefit